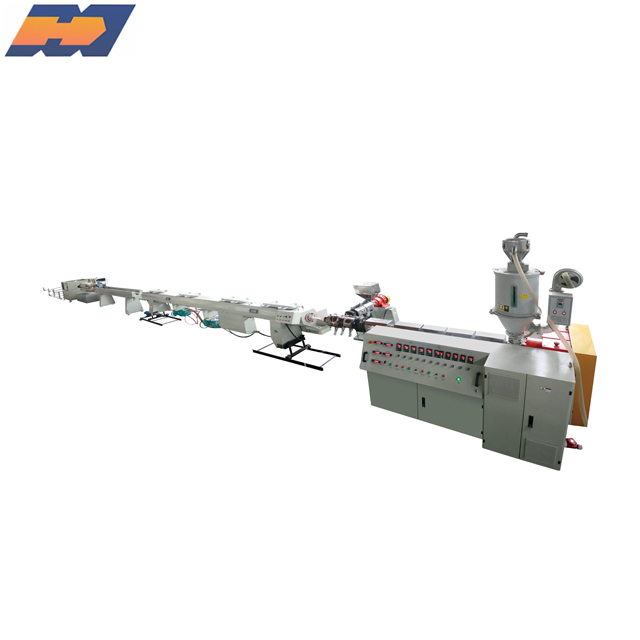

PPR Pipe Production Line

| ID:181850 View:892次 |

| Date Listed: | 2019-05-17 10:27:32 | Country: | China»Jiangsu»Zhangjiagang |

| Poster: | Steven | Company: | Zhangjiagang Huaming Machinery Co., Ltd. |

| Location: | Gengyu Village, Jinfeng Town | Website: | Zhangjiagang Huaming Machinery Co., Ltd. |

| Email: | saya@huaming.cn | Mobile: | 008618921980633 |

| Fax: | MSN: |

1. Usage & scope of application The production line is mainly used to produce pipe from PP-R resin. It also can PP, PPB, PPH resin as raw material to produce pipes. If appropriately change the configuration, it can be used to produce special pipes such as PPR glass fiber reinforced pipe and nano antibacterial pipe, etc. 2. Machine composition & Characteristics The advantages of this PPR pipe production line are as follows: unique structure, advanced automation, easy operation, and stable continuous production. The PPR pipe produced by this line is the first choice for home water pipe transformation because of the advantages as follows: heat resistance, pressure resistance, heat preservation and energy conservation, long service life and economic, etc. Process flow chart: raw material + master batch → mixing → vacuum feeding → raw material drying→ single screw extruder → marking line extruder → spiral mould → diameter control unit → spray vacuum setting box → cooling water tank → inkjet printer → caterpillar tractor → fixed length cutter → stacker. Main characteristics: Extruding machine: the single screw extruder uses slot barrel and new model BM high efficient screw with high screw rotating speed, capacity and strong plastification Extruding mould: it uses spiral shunt type die which can make the discharge even, also easy to adjust and can remove the extruding weld marks. Vacuum setting device: vacuum spray box, spray cooling box or high efficient cooling water tank which touches water are all made by stainless steel. Tractor: two claw belt type or rubber caterpillar tractor to meet the production requirements of different pipes. Cutter: non-chip rotating blade cutting Stacker: auto-reversing type or roller type stacker. Small diameter pipe can use double disk pipe winder according to customers’ requirement. We have many kinds of electric control system for choice such as PLC auto control system. The production speed will be high and ....

Please Note that this information was issued on BestB2B.com!

Insulation Panel,roof panels2024-01-29

EPS sandwich panel2024-01-29

Insulated Metal Panels Increas2024-01-29

Insulated Metal Roof Panel2024-01-29

Light Insulated Metal Wall Pa2024-01-29

Insulated Metal Wall Panels2024-01-29

Insulated sandwich panels / In2024-01-29

Trapezoidal Roof Panel / Wall2024-01-29

100G QSFP28 SWDM4 100m LC Opti2024-02-01

100G QSFP28 SR4 100M MPO Optic2024-02-01

200G QSFP56 SR4 100m MPO Optic2024-02-01

400G OSFP SR8 100m MPO Optical2024-02-01

400G QSFP-DD LR8 10KM LC Optic2024-02-01

400G QSFP-DD LR4 10KM LC Media2024-02-01

400G QSFP-DD 4x100G LR 10KM 2024-01-29